Overview

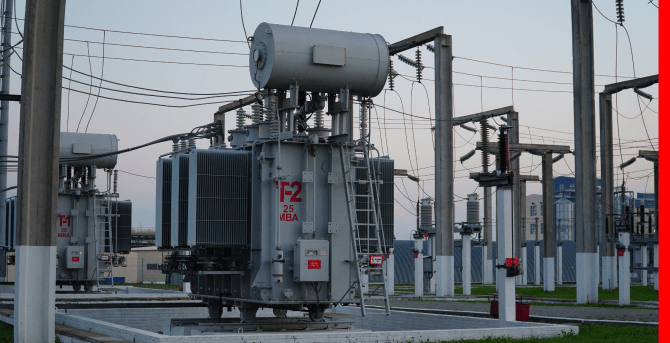

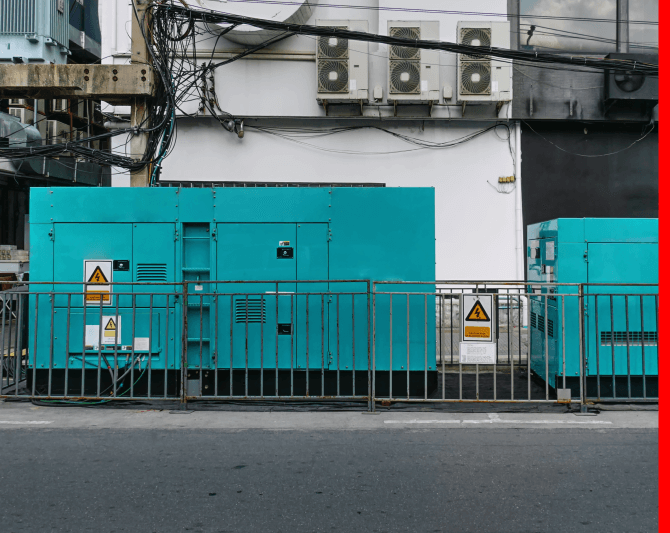

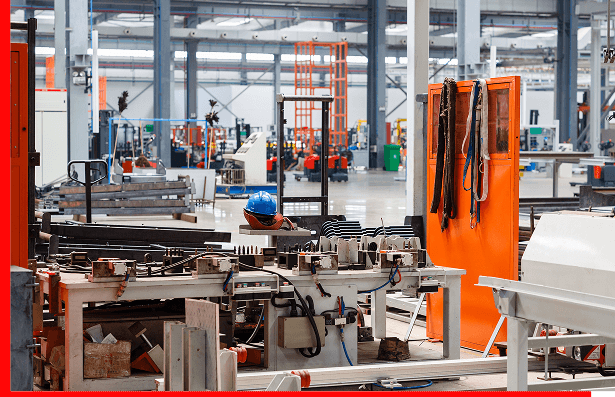

A manufacturing facility in Victoria faced frequent power interruptions, causing production delays, increased downtime, and financial losses. To mitigate these issues, the company decided to upgrade its power transformer and main switch to support a generator backup system.

Additionally, the upgrade was undertaken to increase the size of the power supply, allowing for the addition of more production machinery in the facility. As the trusted industrial electrical contractors in Melbourne, Aus-Tech was tasked with the upgrades, from sourcing the right product to installation and testing.

This case study explores our work with the client, as well as the benefits achieved through investing in said electrical system upgrades.